Pneumatic (Air compressor driven) liquid booster pumps/system

Compressed Air Driven Liquid Booster Pump-DGM/DGG/DGGD Series

We offer the most complete range of Air driven liquid pump models in the industry measured for:

A. Capability of ultimate pressure, flow or output horsepower.

B. Compatibility with a broad variety of liquids, such as oil, water and chemical applications.

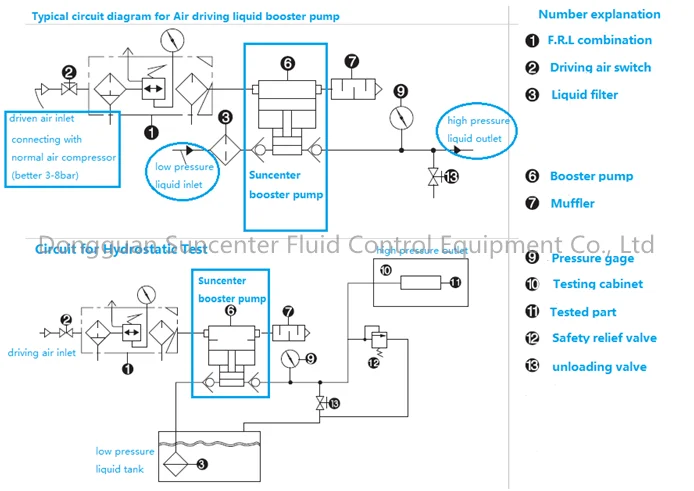

SUNCENTER pumps are air driven at a drive air pressure of 1bar to 8bar (14.5 psi to116 psi) by the normal air compressor. Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is regulated by a pilot operated 4/2 way valve.

Suncenter pumps feature a large air piston joint to a smaller diameter plunger. The pressure ratio is the difference of these two areas and is the method of determining maximum outlet pressure. Higher pressures obtained by using higher pressure ratios.Suncenter model numbers reflect the pumps nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple air regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal liquid pressure can be calculated.

SUNCENTER pumps are self priming. In general it is not necessary to use an air line lubricator.

The liquid to be pumped flows into the suction chamber by the up-stroke of the drive piston. By this suction effect, the inlet check valve is opened and the outlet check valve is closed. The down-stroke generates the pressure at the liquid side. The inlet check valve is closed and the outlet check valve is opened by the generated pressure. SUNCENTER liquid pumps cycle automatically, where the pressure is built up the numbers of cycles slow down, the pump stops automatically when the output pressure forces are equal. The pump restarts with a slight drop in the outlet pressure or an increase in the air drive pressure. Pump performance can be affected by a number of conditions, such as freezing of muffler or pilot valves (which is caused by moisture in air lines), inadequate inlet air line sizes and dirty filers. Don’t reduce the indicated port sizes and consult SUNCENTER for exact flow conditions not shown in charts.

Applications include:

Pressure testing

Burst(Hydrostatic) testing

Work holding/power clamping

Jacking/lifting

Valve actuator control

Hydraulic cylinder actuation

Press safety overload devices

Roller tensioning

Metering

Precision lubrication and spraying

Liquefied gas transfer

Key features include:

Compressed Air driven - no electricity required (connect to normal air compressor)

In order to extend the lifetime of the pump, the driving air pressure should

not be higher than 8 bar

No airline lubricator required

Pressures to 640Mpa (6400 bar)

Wide range of models with different ratios

Built-in-cooling on most models

Easy to install, operate and maintain

Best price / performance ratio

No heat, flame or spark risk and explosion proof

Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter pump will automatically start, keep the loop pressure constant

DGM Series Liquid Pumps(Single acting, single air drive head)

They have aluminum bodies, with oxidation treatment and wetted materials of carbon steel or stainless steel, which depending on different service liquid. Material of stainless steel, making them an excellent choice of water application.

Portable design.

High quality seals, long service life available

Easy to install, operate and maintenance.

Explosion proof and no electrical power required.

Model Pressure Boost Ratio Driven air pressure PL Formula to calculate outlet pressure MAX Outlet

Pressure(bar)* Liquid inlet Connection Liquid outlet Connection MaxFlow rate(L/min)**

The outlet liquid pressure=Driven air pressure*boost ratio

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

DGG Series Liquid Pumps(Single acting, single air drive head)

DGG pumps have aluminum bodies and wetted materials of stainless steel or carbon steel ,which

depends on different service liquid. Materials of stainless steel, make them an excellent choice

of water application. High quality seals, long service life available.

Technical specification

Model Pressure Boost Ratio Driven air pressure PL Formula to calculate outlet pressure MAX Outlet

Pressure(bar)* Liquid inlet Connection Liquid outlet Connection MAX Flow (L/min)

The outlet liquid pressure=Driven air pressure*boost ratio

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

DGGD Series Liquid Pumps(Double acting, single air drive head)

They are characterized by the same features as the DGG pumps single acting, single air drive head types,

but they have less pulsations and deliver approx. 50 % more flow.

Technical specification

Model Pressure Boost Ratio Driven air pressure PL Formula to calculate outlet pressure MAX Outlet

Pressure(bar)* Liquid inlet Connection Liquid outlet Connection MAX Flow (L/min)**

The outlet liquid pressure=Driven air pressure*boost ratio

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

Suncenter DLS Series Pneumatic (Air driven) Liquid Booster System

Suncenter- DLS Series Pneumatic(Air driven) Hydraulic Power Packs

SUNCENTER- Hydraulic power packs(Liquid pump system) are compact and delicacy solution tailored to customer specific requirements with air driven liquid pumps as well as all accessories to be fitted and installed on the frame or in closed cabinet.

To operate this system, the pressure gauges, valves and pressure regulators have to be fitted on panels. The outlet pressure is easily to be set through a simple air regulator. The pump stops automatically when this end pressure is reached and restarts with a slight drop in the outlet pressure or an increase in the air drive pressure. SUNCENTER Hydraulic power packs are available with wide range of pressure ratios make these series of pumps ideal for powering a variety of oil/hydraulic operations. The maximum operating pressure up to 640 MPa.

As the pressure will be generated by means of a pneumatically operated pump,the electric connection will not be necessary. To operate this system, the air driven liquid pump have to be equipped with the air control unit combined filter and water separator, pressure-regulating valve, pressure control gauge as well as manual relieve valve. In this operation, the pump will be mounted to the stainless steel tank in the closed cabinet in a compact and space saving manner. Pressure gauges, valves and pressure regulators will be fitted on panel.

The desired operating pressure can be attained by adjusting the driving air pressure. When the driving air pressure and the output pressure reach the balance, the pump stops filling pressure and the output pressure stays at the preset value. This hydraulic unit can be used for all kinds of pressure testing and test tools for research and test institutes or for other functions requiring a determined pressure.

DLS Liquid (hydraulic) booster system = Liquid pump+ following valves, gages, and parts

The standard liquid pump system including following parts:

Air –driven liquid booster pump (DGM/DGG/DGGD Three series for choosing)

Stainless steel (carbon steel) material cabinet (Three models for choosing)

F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

Driven air switch (Pump starting switch), driven air pressure gauge, water tank

Liquid inlet/outlet switch, high pressure liquid guage, unloading valve, interconnecting pipes etc.

And we could also customize it according to clients’ special requirement.

DLS series Liquid Pressure Booster Pump System-The hottest selling Model C cabinet

How to Select Suncenter Air Driven Liquid Boosters/Systems?

In order to choose suitable liquid booster pump or systems for you,

please kindly reply us the following questions:

1.What is the liquid you want to booster?

2. What outlet liquid pressure do you want?( )bar

3. What driven air pressure (of your air compressor) can you offer?( )bar,

Because our booster is completely air operated and no need any electricity

4. What outlet liquid flow rate do you need?( )L/min

Dongguan Suncenter Fluid Control Equipment Co.,Ltd All rights reserved Guangdong ICP for 粤ICP备16111379号-1 ![]()

Our main products including:

Air Driven Gas Booster Pump,Air Driven Liquid Pump,Air Amplifiers

Air Driven Gas/Liquid Booster Stations,HFC-227ea/FM200 filling machine,

High Pressure Hydraulic/Pneumatic Test Machine,Burst/Hydrostatic pressure testing machine ,Impulse Testing Machine,etc.)